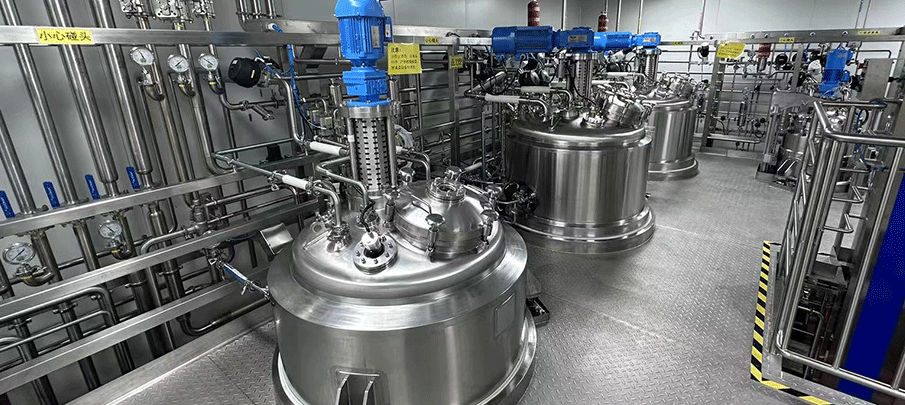

This stainless steel reactor is optimized for fungal fermentation characteristics. The kettle body is made of 316L food grade stainless steel, which is corrosion-resistant and can adapt to the acidic and alkaline environment of fungal fermentation. The volume ranges from 50L to 10000L, meeting the needs of different production scenarios. The inner wall is polished with high-precision mirror finish, with a roughness of Ra ≤ 0.4 μ m, reducing the probability of mycelium adhesion and facilitating cleaning and sterilization. The temperature control module adopts a jacket type heat exchange structure combined with high-precision platinum resistance sensors, which can accurately control the temperature between 10-120 ℃, with fluctuations within ± 0.5 ℃, providing a stable temperature environment for fungal growth and metabolism. The stirring device is designed with a bottom mounted structure, and the stirring blade is a combination of screw belt and blade structure. The speed can be infinitely adjusted from 20-250r/min, which can break the aggregation of mycelium, improve the uniformity of material mixing and mass transfer efficiency. The environmental parameter regulation system can accurately monitor and adjust pH and dissolved oxygen. The sterilization component supports fully automatic in-situ sterilization, using a 121 ℃ saturated steam sterilization mode with a pressure of 0.12MPa, and the sterilization duration can be flexibly set. The intelligent control system is equipped with PLC and high-definition touch screen operation terminal, which can complete parameter preset, real-time data monitoring and other functions, providing reliable guarantee for fungal fermentation production and assisting in stable and efficient production.